The Role of AI in Transforming Manufacturing

In today's rapidly evolving manufacturing landscape, businesses increasingly rely on Artificial Intelligence (AI) to enhance production efficiency, reduce operational costs, and drive innovation. From automating routine tasks to enabling predictive maintenance, AI plays a crucial role in transforming manufacturing processes across all sectors.

AI technologies encompass a wide range of applications aimed at optimizing manufacturing operations and supporting industrial professionals. This includes everything from intelligent robotics that assist in assembly lines to advanced quality control systems that enhance product accuracy. Whether you are a small workshop or a large manufacturing plant, leveraging AI solutions can significantly impact your organization’s success.

One of the primary benefits of adopting AI in manufacturing is its ability to streamline various processes. Automated systems can handle inventory management, equipment monitoring, and production scheduling, freeing up valuable time for professionals to focus on critical tasks.

As manufacturing organizations increasingly adopt digital technologies, the need for robust data security and compliance with industry standards becomes paramount. AI-driven security measures help protect sensitive production data, ensuring compliance and fostering trust between manufacturers and their stakeholders.

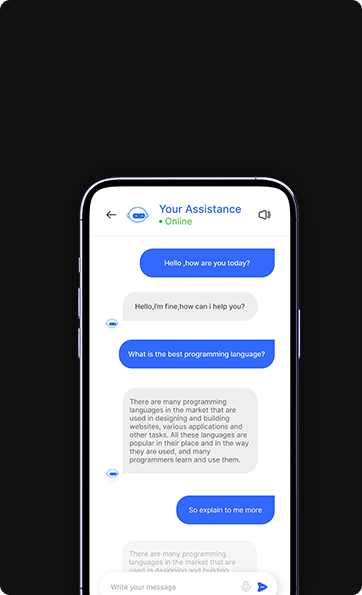

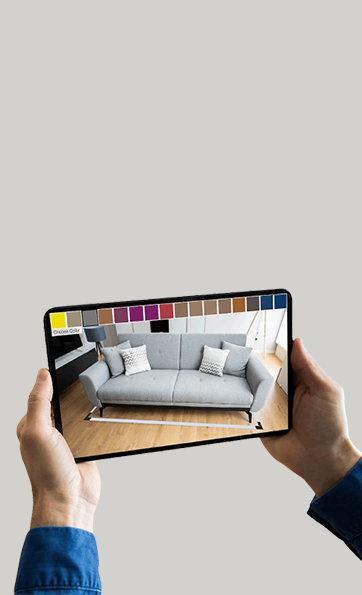

AI also enhances product quality by personalizing manufacturing processes. Through data analysis, manufacturers can tailor production techniques to specific product requirements, improving outcomes and customer satisfaction. AI solutions enable manufacturers to offer efficient support through various channels, ensuring timely responses to production inquiries.

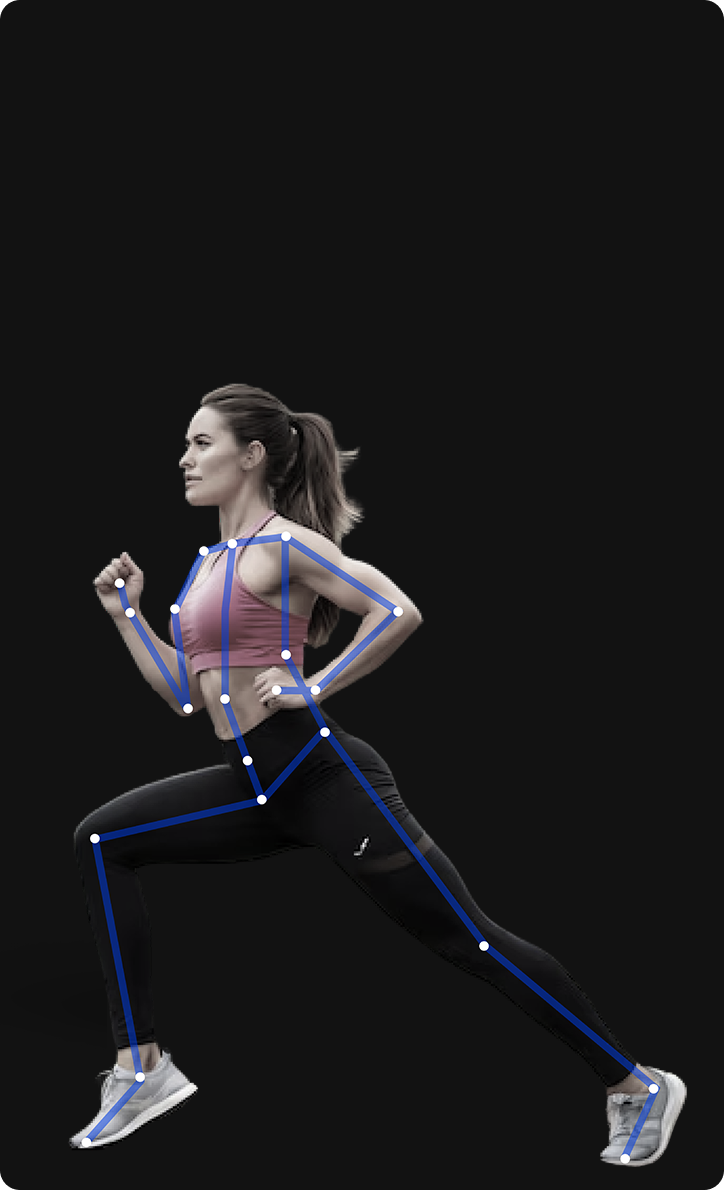

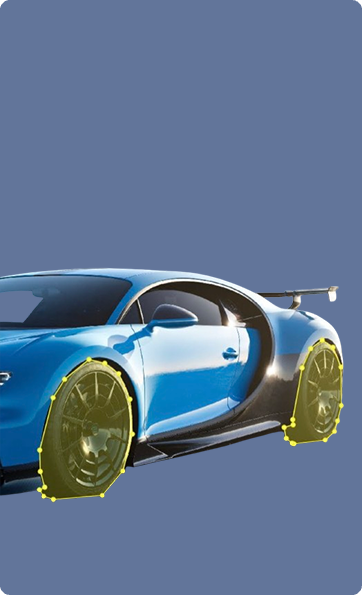

AI technologies facilitate the collection, analysis, and visualization of manufacturing data, transforming raw information into actionable insights. By harnessing the power of data analytics, manufacturing organizations can identify trends, optimize production schedules, and streamline operations, leading to better product quality and increased efficiency.

Ensuring Seamless Manufacturing Operations

Disruptions in manufacturing, such as equipment failures or supply chain interruptions, can severely impact operations. AI technologies offer robust monitoring and management solutions, ensuring that critical data is safeguarded and can be quickly addressed in case of unforeseen events.

This level of preparedness helps maintain seamless operations, safeguarding your reputation and ensuring consistent production quality. AI technologies streamline processes such as quality control, inventory management, and production workflows, ensuring that manufacturing organizations can adapt quickly to changing market conditions.

Empowering Manufacturing with Data Insights

AI-driven analytics tools can process and analyze vast amounts of manufacturing data, extracting meaningful insights that support operational decision-making and improvements.

AI solutions have evolved into an indispensable component of modern manufacturing success. From AI-powered robotics and predictive maintenance systems to enhanced analytics, each solution plays a crucial role in empowering manufacturing organizations to thrive in a technology-driven world. By embracing these AI technologies and partnering with the right service provider, your organization can unlock its full potential, achieve operational excellence, and stay ahead of the competition in today's dynamic manufacturing market. In conclusion, AI solutions have become the backbone of modern manufacturing, providing a multitude of benefits that drive growth, efficiency, and improved product quality.